ATA-AOM 009.

As you are all aware ATA has developed a new route structure for re-accreditation.

What changes for you?

The simple answer to this question is very little. The reason for this is the IMI has chosen to mirror the current British Welding Standards. This means we can carry out the first steps towards your re-accreditation ON SITE.

What does this mean to you and your technicians?

The new AOM 009 (BS1140 & BS4872) has officially become the recognised starting point for renewing an ATA ID card.

Once technicians have passed this new AOM they can proceed with the rest of their ATA Panel re-accreditation.

This module is used as a prerequisite but unlike your ATA accreditation your AOM-009 is like your current British standard. It has a 2 year validity period.

How does this help you?

First and foremost a reduction in cost. The reason for this is that there is no need for multiple testing for both ATA and PAS125.

As this certification can be carried out on site there is no need to send your technicians off site incurring unnecessary costs i.e. travel, overnight expenses and reduced loss of production.

The certification being carried out on site has a number of advantages. Your technicians will be in a familiar working environment and the equipment they use will not be alien to them.

ATA-AOM 030

What is this?

AOM-030 we give your technicians a standardised sill section individual to the delegates, this removes the risks of overworked areas of a vehicle clashing.

The AOM-030 Sill section repair will be carried out in the work place. This will give the technician the best possible chance of achieving the desired standards.

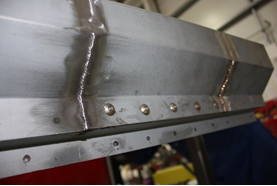

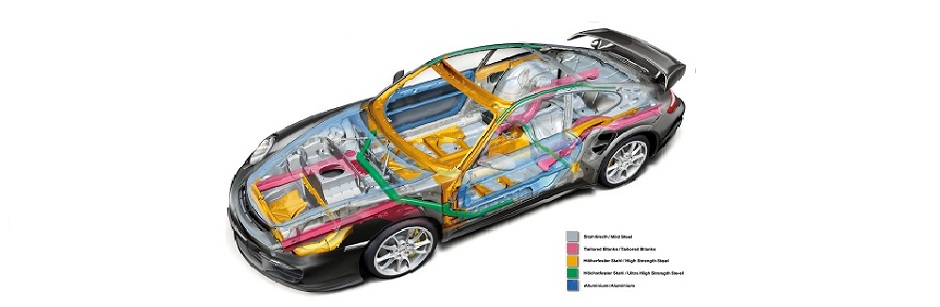

This module is about the replacement of a welded section within the construction of a vehicle bodyshell. The candidate will be required to cut a specified section from a welded panel (i.e. a sill section) without causing damage to other vehicle systems or the vehicle structure. The candidate will cut a section from a new panel and replace the section into the vehicle body using techniques such as spot welding, MAG welding, bonding, riveting, and MIG Braze. The candidate must be able to ‘dress’ the welds to a finish where the repaired section is ready to accept body filler to a depth of no more than 2mm. The candidate must access the correct repair information / specification and use this information to carry out the repair to the vehicle bodyshell. Note that this exercise will mainly be carried out on a rig, but the competence required will be similar to those used when repairing a vehicle body shell.

ATA-AOM 028

IMI are pleased to announce that AOM 028 is now available as a standalone module. This module provides another option for accident repair workshops to be compliant with the requirements of BS10125, in relation to bonding and mechanical fastenings.

AOM 028 is about the replacement of a welded section, within the construction of a vehicle body shell. The candidate will be required to cut a section from a new panel and replace the section into the vehicle body using techniques such as spot welding, MAG welding, bonding and riveting.